Is Health Surveillance required in your workplace?

Health surveillance is a system of ongoing health checks.

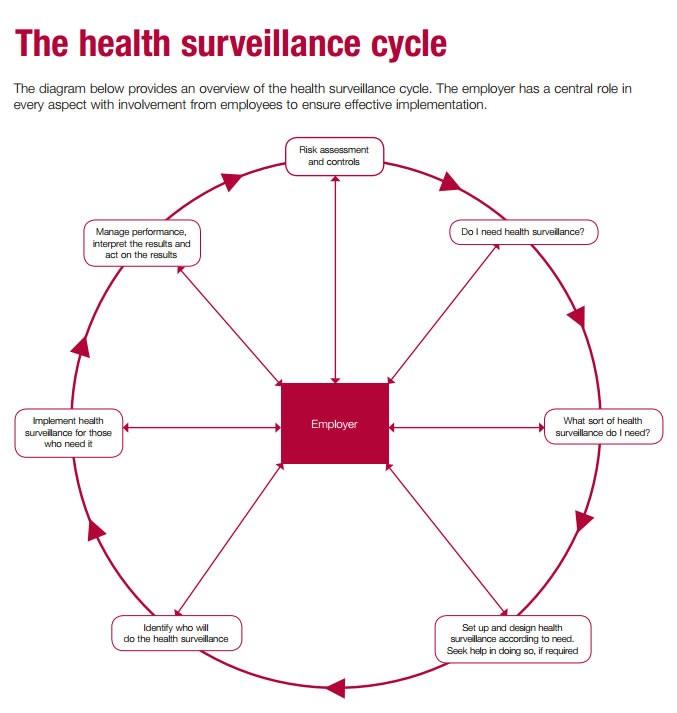

These health checks may be required by law for employees who are exposed to noise or vibration, ionising radiation, solvents, fumes, dusts, biological agents and other substances hazardous to health, or work in compressed air.

Health surveillance can sometimes be used to help identify where more needs to be done to control risks and where early signs of work-related ill health are detected, employers should take action to prevent further harm and protect employees.

So, this week I thought that I would look at this subject because I am aware that some companies, whilst providing the relevant RAMS, PPE etc. do not however, carry out the required health checks on their employees.

Is Health Surveillance required in your workplace?

Occupational health provision is concerned with the prevention, monitoring and treatment of work related disease and ill-health. Health surveillance is monitoring carried out work on individuals to check for an identifiable condition, e.g. noise induced hearing loss.

When is health surveillance required?

The Management of Health and Safety at Work Regulations 1999 require that employees are provided with such health surveillance as is appropriate having regard to the risks to their health and safety as identified by the assessment. HSE guidance recommends that such health surveillance is warranted when:

- there is an identifiable disease or health condition related to the work concerned

- it is likely that the disease or condition may occur

- there are valid techniques are available to detect it the early signs of the disease or health effect

- these techniques do not pose a risk to employees.

The Control of Substances Hazardous to Health Regulations 2002 contains similar requirements but also require health surveillance where exposure to a specific list of materials is involved (Schedule 6). The Approved Code of Practice to the Regulations also lists specific types of work where health surveillance is required under the above criteria.

If employees are exposed to risks from:

- asbestos,

- radiation,

- lead,

- vibration or noise, or

- artificial optical radiation,

health surveillance may be required. Regulations for the Control of Electromagnetic Fields at Work Regulations came into force in April 2016, which also require health surveillance in certain circumstances. If necessary, contact us at The Wilkins Safety Group for specialist advice.

Health surveillance is important for:

- detecting ill-health effects at an early stage, so employers can introduce better controls to prevent them getting worse

- providing data to help employers evaluate health risks

- enabling employees to raise concerns about how work affects their health

- highlighting lapses in workplace control measures, therefore providing invaluable feedback to the risk assessment

- providing an opportunity to reinforce training and education of employees (eg on the impact of health effects and the use of protective equipment)

Your risk assessment should be used to identify any need for health surveillance. You should not use health surveillance as a substitute for undertaking a risk assessment or using effective controls.

Health surveillance can sometimes be used to help identify where more needs to be done to control risks and where early signs of work-related ill health are detected, employers should take action to prevent further harm and protect employees.

When putting in place a health surveillance programme, avoid blanket coverage for all employees as it can provide misleading results and waste money.

When is exposure or health monitoring required?

Health monitoring is needed where an employee’s fitness for work is a key element of their safety and that of co-workers. Examples are diving and confined space work.

Exposure to specific hazards should be monitored at source periodically, e.g. measurement of noise, monitoring of exposure to fumes and dusts etc.

The purpose of this is to check that exposure is within statutory limits and to assess the level of risk.

Difference between health records and medical records

We must stress here that no employer has the right to see an employee’s medical records – these are confidential to the employee and his/her doctor.

However, the results of health surveillance are recorded in a health record. This should include the outcome of the test/check that was performed and the decision made by the occupational health professional as to the employees continuing fitness for task. This health record should be made available to management so they are aware of the continuing fitness for work of the employees.

Other details may have been taken by the health professional during the health surveillance. These would form part of the medical record of the employee and will be confidential.

Legislation and guidance

The main duties for the management of health risks at work and for health surveillance are contained within:

- The Control of Substances Hazardous to Health Regulations 2002

- The Health and Safety at Work etc. Act 1974

- The Management of Health and Safety at Work Regulations 1999.

In addition, there are regulations which require health surveillance for particular activities which involve exposure to lead, noise, vibration, optical radiation, asbestos, ionising radiation, diving activities, working in compressed air, and safety critical tasks in the rail industry.

The Reporting of Injuries, Disease and Dangerous Occurrences Regulations 2013 (RIDDOR) contain requirements for the reporting of certain diseases to the authorities.

Recommendations for employers:

- carry out risk assessments to identify work which requires routine exposure monitoring, health monitoring and/or surveillance, obtaining advice as necessary from an Occupational Health provider

- implement a programme of exposure monitoring, if needed, with input from an Occupational Hygienist

- identify health checks to be carried out at the start of employment in a role and periodically throughout employment

- consider what occupational health support may be needed to assist employees returning to work after long term sickness absence

- determine whether the organisation would benefit from health promotion campaigns and other health initiatives (i.e. going beyond the legal requirements)

- monitor sickness absence for illnesses which may be work related, or made worse by work

- implement an occupational health programme to include all of the above items, with input from a competent Occupational Health provider as necessary

- ensure that suitable records of health surveillance and occupational health provision are maintained confidentially and retained for a suitable period (usually at least 40 years)

- check that arrangements are in place for identifying and reporting diseases in accordance with RIDDOR

- review the arrangements periodically.

Case law

A Bristol company was fined £100k and ordered to pay £30k costs having exposed employees to hazardous chemicals over a 4-year period.

This lead to allergic contact dermatitis with one employee suffering four years of skin blistering, cracking and splitting

Help available from The Wilkins Safety Group Ltd

Here at the Wilkins Safety Group we can help clients with:

- Online training in areas such as Asbestos, COSHH, Noise at Work and Stress in the Workplace. – See below about our new Online Training

- Model Policy on Occupational Health Provision and Health Surveillance

- WSG Guide on Occupational Health Provision and Health Surveillance

- Related WSG Guides ‘Asbestos Management’, ‘Radiation’, ‘Vibration at Work’, ‘Noise at Work’, ‘Sensitisers and Allergens’, COSHH/Hazardous Substance Control’.

If you would like any further help or support, please please contact us by phone 01458 253682, email or via our Facebook page or by Twitter.

Taunton & Somerset CPD Group at The Exchange House Taunton

Please remember that we now run these CPD events at the Exchange House, 12 – 14 The Crescent, Taunton TA1 4EB on a fortnightly basis

The next of the CPD events is listed below.

As previously requested, if you could let us know whether or not you can attend it would be greatly appreciated. Also, if you would like to give a talk, or know of somebody who would, please contact Jon at [email protected]

Our next Seminar will be on Wednesday 12th June 2019. Could you please arrive by 12:30pm prompt.

Our speaker for this one is Sam Hagley of Venesta who will talk about Designing Washrooms for different applications

If you haven’t already booked your place, or if you are not on the CPD Seminar mailing list but would like to be please drop Jon an email and he will deal with your request.

As per our last one if you could let Jon know whether or not you can attend within 7 days of receipt of his email, it would be greatly appreciated.

Contact Details [email protected] 07831 714199 or 01458 253682

Please Note: This will be the last one until 11th September.

The Wilkins Safety Group have now launched our much-anticipated health and safety e-learning

Great News!! We have now launched our Online e-learning courses in Health and Safety that are suitable for most organisations.

You can book as many of each of the courses as you need. We think our courses offer great value for money but to help you further, the more places you book on a course, the cheaper it becomes!

Simply click on any of the courses listed to find out what the course will offer you. if you like what you see, you can book the course online and we will send you individual logins for everyone undertaking the training. On successful completion of the course, certificates will be issued.

For more information and to book your course/s please go to: https://wilkinssafety.co.uk/courses/

We hope you find these useful and we will be adding new courses in the near future.

Why use online health and safety e-learning?

There are many e-learning benefits: You can drastically cut your risks and improve effectiveness. Staff retention and productivity will increase and safety will improve. It’s that simple.

The health and safety e-learning training courses are dynamic, engaging and very interesting. As the content is interactive your staff will learn quickly, retain more knowledge and enjoy the training.

The self test section means that they get to see how much they have learnt and if necessary, revisit any areas that they have failed. There is an option to print a certificate for each user who has passed which is personalised with their details.

By providing high quality accurate health and safety information to your staff you will build a culture of safety and help increase staff retention, productivity as well as protecting yourself from damaging and expensive legal action.

One of the major e-learning benefits is the fact that the system provides an audit trail which tracks your staff progress and you can make an accurate assessment of their understanding.

How is the training delivered?

The Wilkins Safety Group e-learning system is delivered over the Internet, all you need to access your system is a PC with Internet browser (you will also need your user name and password).

The system is hosted on our secure server. The server carries an SSL certificate and all data is encrypted for maximum security. We manage the server that means that you have no IT worries.

What is the cost of these courses?

Companies will be able to buy credits. Each of these credits will allow 1 allocated person access to 1 course. The cost of these credits will reduce based on the number of credits purchased. See pricing chart below:

| No of Credits | 1-5 | 6-10 | 11-20 | 21-30 | 31-40 | 41-50 | 51-75 | 76-100 | 101-150 | 151-200 | 201-250 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cost of Credit | £19.99 | £17.99 | £16.99 | £15.99 | £14.99 | £13.99 | £12.99 | £11.99 | £10.99 | £9.99 | £7.99 |

Below is the list of the first 16 e-courses that have gone live

- Asbestos Awareness Interactive

- COSHH Interactive

- DSE Equipment

- DSE Workstation Assessment

- Electrical Safety

- Environmental Awareness

- Fire Extinguishers

- Fire Safety and Evacuation

- First Aid

- Food Hygiene

- Food Hygiene Level 2

- Health and Safety Induction Interaction

- Manual Handling

- Protection against effects of Noise

- Risk Assessment

- Stress in the Workplace

The next 14 will be

- Accident Investigation interactive – Every Company boss should know how to do this

- Articulated Forklift Truck Ops – Essential if you have these in your workplace

- Driver Safety Interactive – Something I have touched on in recent newsletters

- Fire Warden Interactive – This for your Fire Wardens

- Home Worker – Do you employ any Home Workers?

- Infection Prevention & Control – Relevant in Hospitals, Care Homes and food establishments

- Lone Working Interactive – There are many lone workers

- Mental Health & Wellbeing – As previously covered in these newsletters

- Office Safety Interactive – An essential for all office workers

- Permit to Work – Do you require a PTW where you are going to work?

- Personal Protective Equipment – Make sure your employees are fully aware of the PPE they need

- Safety Hazards – Are you aware of the Safety Hazards in your workplace?

- Slips Trips and falls – Main cause of accidents in the workplace

- Working at height interactive – Main cause of accidents on construction sites

We would love to hear any expressions of interest or of any other courses that you would like us to develop.

Worker suffers life changing injuries in fall

Company sentenced after worker suffers life changing injuries in fall

A company, two directors and a self-employed contractor have been sentenced and fined after an electrician fell two storeys through an  unprotected stairwell.

unprotected stairwell.

Manchester and Salford Magistrates Court heard how, on 1 December 2016, Mr T Quirk was carrying out electrical work at Mile House, Main Road, Worleston, Nantwich, Cheshire, CW5 6DH. This property was owned and was being refurbished by self-employed contractor Mr Steven Dixon. Mr Quirk, whilst exiting the loft, fell from a damaged Youngman Board spanning the stairwell, landing on the concrete floor below and suffering multiple fractures, a bleed on the brain and facial nerve damage.

An investigation by the Health and Safety Executive (HSE) found that two directors of the company, Mr Karl Grice and Mr Sean Mullan, were fully aware, along with Mr Dixon, that the damaged board was being used as a makeshift ladder and had used it themselves. They were also aware of the unprotected edges of the stairwell, but had not carried out risk assessments, identified which control measures were needed, or implemented suitable safety measures to protect workers on site.

Green Generation Renewable Services Ltd of Knowsley Industrial Park, Liverpool, pleaded guilty to breaching Regulation 15 (2) of the Construction (Design and Management) Regulations 2015 and was fined £20,000 and ordered to pay costs of £2,548.28

Mr Karl Grice of Highmarsh Crescent, Newton-Le-Willows, pleaded guilty to breaching Regulation 15 (2) of the Construction (Design and Management) Regulations 2015, by virtue of Section 37 of the Health and Safety at Work etc. Act 1974 and was sentenced to 16 weeks in prison (suspended for 18 months) and fined £1,000 and ordered to pay costs of £2,000.

Mr Steven Paul Dixon of Warmingham Grange Lane, Sandbach, pleaded guilty to breaching Section 3 (2) of the Health and Safety at Work etc. Act 1974 and was sentenced to 16 weeks in prison (suspended for 18 months) and fined £1,000 and ordered to pay costs of £2,000.

Mr Sean Mullan of Argyle Road, Garston, Liverpool, pleaded guilty to breaching Regulation 15 (2) of the Construction (Design and Management) Regulations 2015, by virtue of Section 37 of the Health and Safety at Work etc. Act 1974 and was fined £1,500 and ordered to pay costs of £2,000.

After the hearing, HSE Inspector Deborah Walker said:

“This incident could have so easily have been prevented. Falls from height remain one of the most common causes of work-related injuries and the risks associated with working at height are well known. Those in control of work have a responsibility to devise safe methods of working and to provide the necessary safety measures.”.

Worker crushed by falling metal frame

Engineering company fined after worker crushed by falling metal frame

A Warrington engineering fabrication company has been sentenced today after a worker suffered severe crush injuries when a metal frame he was moving toppled from a fork lift truck.

Liverpool Magistrates’ Court heard how, on 11 October 2017, the employee of J L Engineering (Rixton) Ltd, together with another worker, was moving a trestle frame using a fork lift truck (FLT). In an attempt to release the frame, which was catching the wheels of the truck, the driver loosened the securing straps. This caused the frame to topple from the FLT onto the employee who suffered multiple severe fractures and an erupted bladder. He is still receiving medical treatment and has been unable to return to work.

An investigation by the Health and Safety Executive (HSE) found the company had not prepared a suitable risk assessment or lifting plan for lifting operations and had failed to recognise the risks associated with the way its employees were working. Employees were not adequately trained or instructed in methods of carrying out lifting operations safely.

J L Engineering (Rixton) Ltd of Chapel Lane, Rixton, Warrington pleaded guilty to breaching of Section 2 (1) of the Health and Safety at Work etc. Act 1974 and has been fined £22,000 and ordered to pay costs of £5,895.32.

After the hearing, HSE inspector Catherine Lyon said:

“The employees injuries in this case were life-changing and could have been fatal. Employees were put at risk as a result of the company allowing fork lift trucks to be used without the appropriate training and monitoring of drivers.”

“Employers have a responsibility to provide safe methods of working and to ensure workers have the necessary information and training to enable them to work without risk.”

Remember

Unlike other organisations who send out newsletters giving you a little titbit of information, then stating that if you want to follow the full link or read the full story or get more information you must pay to subscribe to their service.

- Our newsletter service is FREE,

- The links we supply are FREE,

- The helpline advice is FREE.

If you find this newsletter service of use and you think others might also find it useful, then kindly pass it on and ask them to subscribe for free, so they can continue to receive it in their own right.

Also contact us if you have a particular health and safety subject or question you would like covered

If you have any queries on any health and safety matter, please contact Jon Wilkins on 01458 253682 or by email on [email protected]