An organisation’s culture can have as big an influence on safety outcomes as the safety management system.

management system.

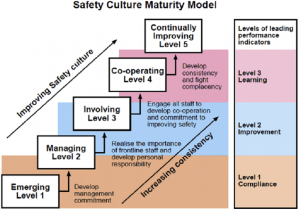

The safety culture of an organisation relates to the values, attitudes, perceptions, competencies, and patterns of behaviour that determine a company’s commitment to health and safety management.

Company values are vital in setting the direction and tone of a company’s health and safety culture. So, this week I thought that I would look at ways of creating a good health and safety culture in your company.

So, what are the benefits of a positive health and safety culture?

There are many benefits to having a positive culture in your company:

- Lower absenteeism – if people are fit and healthy they’ll remain at work.

- Lower wage bills – no doubled-up costs of sick pay and overtime cover to fill the gaps.

- Reduced repairs & re-working – when things are done right there is less injury, damage or out of spec product meaning less costs for repairs, re-working and waste disposal.

- Happier workforce – if employees feel safe and secure at work, they’ll be happier.

- Lower staff turnover – if employees don’t think the grass is greener elsewhere, companies will be paying a lot less to replace workers who’ve left. And a lot less on recruitment and training too.

- Reduced risk of fines – if the HSE were unhappy with health and safety practices, companies could be subject to hefty fines.

- Reduced insurance claims – injury and illness claims, property damage and business interruption all cost money. Investing money to reduce claims will save money in the long term.

- Reduced insurance premiums – The better the health and safety performance, the lower the premium.

- Improved productivity, quality & profitability – the presence of positive workplace perceptions and feelings are associated with higher customer loyalty, higher profitability, higher productivity and lower rates of staff turnover.

- More satisfied clients & stakeholders – if quality, efficiency and staff relations are all exemplary a business will have a reputation to reflect that.

So why do you need to tackle behaviour?

Well there are two main reasons:

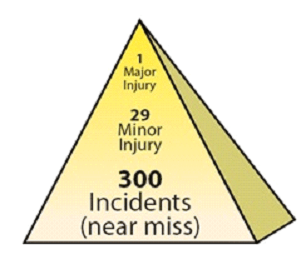

The first is that there is always a direct link between the number of unsafe acts and the number of accidents. Heinrich’s original famous Triangle suggested that there are on average 300 unsafe acts per accident.

However, it has been suggested that there are two million unsafe behaviours per fatality. Yes, you could argue over the exact ratio but it does not matter though – because there will be one.

Let us consider a simple scenario of walking up and down a staircase without holding on to the handrail.

- If the true likelihood of falling down the stairs is 100,000 to 1 and 1M people use the stairs annually – with no-one holding the handrail – then you will have 10 accidents a year give or take.

- If 90% of people, then use the handrail each time then this is reduced to 1 accident a year give or take –

- BUT if we can get 99% to comply then there will be only 1 accident every ten years or so.

For the typical company the majority of accidents will be the result of simple slips trips, falls, manual handling and being struck, so although process safety is of course vital to ensure something catastrophic does not happen, it is virtually impossible to have world class figures without a behavioural approach.

The second reason is that the best definition of safety culture is ‘the way we typically do things around here’.

As in all walks of life a handful of key behaviours will set the tone and the first thing we do in a new situation is to look about and ‘check out what is what”. If we see half the ‘regulars’ acting safely and half unsafely then as a new start or sub contractor we can do pretty much what we want and not stand out.

However, if we can get these key behaviours up over the fabled ‘tipping point’ of 90% or so then it becomes self sustaining.

(These key behaviours will range from simple ‘hold the handrail’, ‘look where you are walking’ and PPE issues through to the quality of a tool box talk, a risk assessment or a safety brief.)

Vision statements and company values are vital, of course, in setting the direction and tone of a company’s health and safety culture but they are not sufficient alone. They may influence the culture but they are not as important as day-to-day behaviour.

Become Pro-Active

Being Pro-Active. Simply asking the workforce why (adopting a curious rather than a challenging manner) an unsafe act is occurring can transform a safety culture.

Even better is setting up workforce teams to ask the question “Is there anything slow, uncomfortable or inconvenient about doing this job safely?” – The higher the proportion of workforce who are involved in this analysis process, the better. They already know what is happening and why, and workers will be more honest with them about the corners they cut.

A key role of management is to action all genuinely ‘high impact: low cost’ solutions promptly and take every opportunity to praise the people involved.

High impact but high cost solutions should of course be considered when appropriate. Many high cost solutions will be impossible to action of course, but the systemic analysis should be recorded to provide justification for rejecting some solutions and implementing others.

What Do We Change?

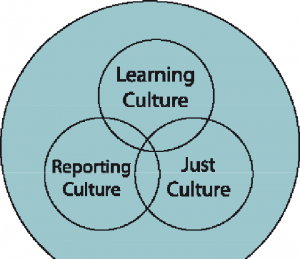

All the research around the Just Culture Model suggests that about 80 to 90% of the causes of unsafe acts are attributable not to the person, but to the company culture and the physical environment.

Only in 10 to 20% of cases are down to a person (provided with suitable and sufficient equipment, supervision and information) going off on a ‘frolic of their own’.

It is vital that our efforts reflect this ratio – 80% or more dedicated to objective analysis of the underlying causal factors.

First, of course, we need to ensure there are no glaring problems with the basics such as training, safety systems, machine guarding, and the day to day safety leadership of the front-line supervision. Such problems often exist, and the methodologies suggested below link back to these issues frequently.

However, we should also proactively look for where there are temptations to cut corners. Stephen Fry jokes that what he does with temptation is ‘give in to it straight away to save time faffing about’ and there is a vital lesson there for safety.

Studies show that where the safe way is slow, uncomfortable or inconvenient, people may be tempted to cut corners and ‘crack on’. This is particularly relevant in circumstances where supervisors may turn a blind eye if directors do.

I remember once visiting a company and finding a machine used for cutting stone, had the safety doors open even though it was in operation. When I looked, I found that somebody had disabled the interlocking guard thereby enabling this safety measure to be bypassed. So, I took this up with the company’s MD who laughed and said ‘Yes, I know about that, it saves us so much time not having the machine stopping and starting all the time’

In the same company I found the first aid kit in the workshop empty, a staircase without a handrail, forklift trucks being used without flashing beacons or operational horns, materials dangerously stacked waiting to fall onto somebody and a loo with a broken seat. This company had very bad safety culture!

Day-to Day Behaviour is Vital – So People Need to Comply and Have a ‘Good Attitude’

Unfortunately, no-one has a bad attitude. Studies show that most of us think we have a good or average attitude.

So when we say “you know who you are” the entire audience points to the person next to them saying “They are talking about you”.

Putting people on courses can help in the short term, just like new football managers can induce a sudden boost in performance. But this honeymoon period does not last and soon there is a return to the old levels of performance – unless we change something.

In football terms the changes might be reorganisation of the team, better organisation at set pieces or improving

fitness levels.

In safety terms we need to change the work environment, values, attitudes, perceptions, competencies, and patterns of behaviour. The maxim ‘if you do what you always did, you get what you always got’ applies here. So isn’t it time to change?

Key aspects of creating an effective culture:

Management commitment: If employees can see that management are committed to health and safety this produces higher levels of motivation and concern for health and safety throughout the organisation.

Visible management: Managers need to be seen to lead by example when it comes to health and safety. Good managers appear regularly on the ‘shop floor’, talk about health and safety and visibly demonstrate their commitment by their actions. It is important that management is perceived as sincerely committed to safety. If not, employees will feel that commercial interests come first, and safety initiatives or programmes will be undermined by cynicism.

Good communications between all levels of employee: In a positive culture questions about health and safety should be part of everyday work conversations. Management should listen actively to what they are being told by employees and take what they hear seriously. Employees should feel confident to report accidents and near misses to enable the company to learn lessons from these.

If you would like any further help or support, please please contact us by phone 01458 253682, email or via our Facebook page or by Twitter.

Taunton & Somerset CPD Group at The Exchange House Taunton

Please remember that we now run these CPD events at the Exchange House, 12 – 14 The Crescent, Taunton TA1 4EB on a fortnightly basis

The next of the CPD events is listed below.

As previously requested, if you could let us know whether or not you can attend it would be greatly appreciated. Also, if you would like to give a talk, or know of somebody who would, please contact Jon at [email protected]

Our next Seminar will be on Wednesday 13th March 2019. Could you please arrive by 12:30pm prompt.

Our speaker for this one is Ian Dryden of SIG Design & Technology will talk about Roof Refurbishment

If you haven’t already booked your place, or if you are not on the CPD Seminar mailing list but would like to be please drop Jon an email and he will deal with your request.

As per our last one if you could let Jon know whether or not you can attend within 7 days of receipt of his email, it would be greatly appreciated.

Contact Details [email protected], 07831 714199 or 01458 253682.

*Early notice of 27th March meeting. Jeremy Miles of Geogrow will talk about Vegetated Retaining Wall Systems

For more details about these and the other forthcoming CPD talks please see cpds to 24th April 2019.