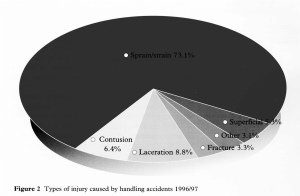

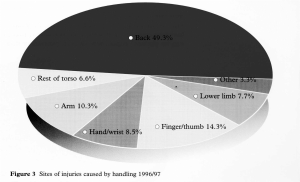

INTRODUCTIONMore than one third of all reportable ‘Over Three Day’ injuries and nearly 10% of ‘Major Injuries’ are associated with manual handling. Many injuries are cumulative, resulting from repeated exposure to manual handling operations. Sprains and strains arise from the incorrect application and/or prolongation of bodily force. Poor posture and excessive repetition of movement can be important factors in onset of injuries. The following diagrams indicate the type of injury and site of injury associated with manual handling accidents. (1996 – 1997 figures)

LEGAL REQUIREMENTSThe Manual Handling Operations (MHO) Regulations 1992 apply to manual handling operations, defined as “any transporting or supporting of a load (including the lifting, putting down, pushing, pulling, carrying or moving thereof) by hand or by bodily force”. Employers are subject to a clear hierarchy of measures to meet duties under the regulations:-

- To avoid hazardous MHO so far as is reasonably practicable

- To assess any hazardous MHO that cannot be avoided

- To reduce the risk of injury so far as is reasonably practicable.

Thus, 1.AVOIDING HAZARDOUS MHO Can the movement etc. of loads be eliminated altogether? Can the operations be automated or mechanised? 2. ASSESSING HAZARDOUS MHO Where a possibility of injury from MHO is indicated, a more specific assessment should be carried out. This is distinct from the everyday judgements which supervisors and others will have to make dealing with MHO. It needs to be broad in approach, identify measures to deal with problems likely to arise and include training provisions. Industry specific data and assessments might prove useful sources of information. The assessment should be recorded and kept readily accessible as long as it remains relevant. It should be noted that assessment is not an end in itself, merely a structured way of analysing risks and pointing the way to practical solutions. The booklet L23 – Guidance on Regulations (MHO Regulations 1992) contains a list of factors that be taken into account when assessing MHO (Schedule 1) and an example of an assessment checklist (Appendix 2). In broad terms, the five factors involved are:-

- The task

- The load

- The working environment

- Individual capability

- Other factors

An aide-memoire checklist is given in booklet L23 as Appendix 2. Typical issues that may be relevant (and for which more advice is provided in booklet L23) include:- The Task

- Is the load held or manipulated at a distance from the trunk?

- Does the task involve

- twisting the trunk?

- stooping?

- reaching upwards?

- combining risk factors?

- excessive lifting or lowering distances?

- excessive carrying distances?

- excessive pushing or pulling of the load?

- positioning the load precisely?

- a risk of sudden movement of the load?

- frequent or prolonged physical effort?

- insufficient rest or recovery periods?

- involve a rate of work imposed by a process?

- The importance of posture

- Handling while seated

- Team Handling

The Load

- heavy?

- bulky or unwieldy?

- difficult to grasp?

- unstable, or are its contents likely to shift?

- sharp, hot or otherwise potentially damaging?

Working Environment

- space constraints preventing good practice?

- uneven, slippery or unstable floors?

- variations in levels of floors or work surfaces?

- extremes of temperature or humidity?

- ventilation problems or gusts of winds?

- poor lighting conditions?

Individual Capability

- Does the task require unusual strength, height etc?

- Does the job put at risk those who might be pregnant or have a disability or a health problem?

- Does the task require special information or training in its safe performance?

Other Factors

- Personal protective equipment and other chatting

3. REDUCING THE RISK OF INJURY The guidance in L23 follows the same structured approach as is taken with assessment detailed in the previous section. It is recommended that an ergonomic approach is adopted, fitting the operations to the individual rather than the other way around. Particular consideration should be given to the provision of mechanical assistance where this is reasonably practicable (e.g. sack truck, hand-powered hydraulic hoist). The workforce should be involved in the process and, again, industry-specific guidance could be a useful source of information. Considerable guidance is contained in booklet L23 (pp20-35) on suggested means to reduce the risk of injury, covering issues such as those listed in (2) above. Other requirements include:- 4. PROVIDING ADDITIONAL INFORMATION ON THE LOAD Where it is not reasonably practicable to avoid employees undertaking MHO at work which involve a risk of their being injured, the employer must also provide general indications and where it is reasonably practicable to do so, precise information on:- (i)the weight of each load (ii)the heaviest side of any load whose centre of gravity is not positioned centrally 5. REVIEWING ASSESSMENTS If there is new information, a change in the MHO or if a reportable injury occurs. 6. EMPLOYEES DUTIES To follow appropriate systems of work laid down by the employer. MANUAL HANDLING RISK ASSESSMENT – DETAILED ASSESSMENT GUIDELINES FILTER

- Appendix 1 of booklet L23 contains a “filter”, developed by HSE, to screen out straightforward cases and thereby help identify situations where a more detailed risk assessment is necessary. The filter is based on a set of numerical guidelines, which seek to set out an approximate boundary within which the load is unlikely to create a risk of injury sufficient to warrant a detailed assessment.

- The application of the guidelines will provide a reasonable level of protection to around 95% of working men and women. NB However, the guidelines should not be regarded as safe weight limits for lifting.

- The guidelines are as follows:-

1.Guidelines for lifting and lowering (These assume the load is easy to grasp with both hands, that the operation takes place in reasonable working conditions and with the handler in a stable body position.) If the handler’s hands enter more the one of the box zones during the operation, the smallest weight figures apply These figures are for relatively infrequent operations (up to 30 operations per hour.) As a rough guide the figures should be reduced:-

- by 30% where operation is repeated 1-2 times a minute

- by 50% where operation is repeated 5-8 times a minute

- by 80% where operation is repeated more than about 12 times a minute

Even if the above conditions are satisfied, a more detailed MHO risk assessment should be made where:-

- the handler doesn’t control the pace of work

- pauses for rest are inadequate or there is no change of activity which provides an opportunity to use different muscles

- the handler must support the load for any length of time

2.Guidelines for carrying Similar to (1) above, assuming that the load is held against the body and is carried no more than 10m without resting. If the distance is longer or the hands are below knuckle height, a more detailed assessment should be made. Where the load can be carried securely on the shoulder without first having to be lifted (e.g. unloading sacks from a lorry) the 10m distance can be exceeded. 3.Guidelines for pushing and pulling The guidelines figures assume that the force is applied with the hands between knuckle and shoulder height. The guideline figure for starting/stopping a load is a force of about 25kg (i.e. about 250 Newtons) for men and 16kg (160 Newtons) for women. For keeping the load in motion the figures are 10kg (100 Newtons) and 7kg (70 Newtons) for men and women respectively. There is no specific distance limit, provided there are opportunities for rest or recovery. 4.Guidelines for handling while seated The basic guideline figure for handling operations carried out while seated, is 5Kg for men and 3Kg for women. These guidelines only apply when the hands are within the box zone indicated in the guidance. If handling beyond the box zone is unavoidable, a more detailed assessment should be made. 5.Other Considerations : Twisting Twisting increases the risk of injury and therefore, if twisting takes place, a detailed risk assessment should normally be made. However, if the operation is relatively infrequent (and there are no other posture problems) the guideline figures in (1) above should be reduced:-

- by about 10% for a 45¼ twist

ADVICE ON SAFE MANUAL HANDLING*There are basic principles that should be followed even prior to lifting the load. The person should ensure that the object is light enough for a one-person lift, check that there are no sharp or abrasive edges, and that the load is equally distributed and stable. If an object is heavy or awkward, a mechanical aid should be employed to assist with the lift. It is important that a clear route is established for the lift, with any obstructions removed, and areas designated for rest breaks and for unloading the object. Proper clothing should be worn for manual handling, such as strong, flat shoes, or anti-slip safety shoes, where necessary; gloves to allow a firmer grip; and durable clothing. Before attempting to lift the object, the worker should establish an effective grip. *For a one-person lift, once it has been established that the load can be lifted safely, the following techniques should be employed:

- the person should stand close to the load and, for stability, spread the feet to shoulder width;

- the knees should be bent and the back’s natural line maintained. Kneeling or bending the knees fully will reduce lifting power;

- the load should be grasped firmly and held close to the body for more leverage and stability;

- the head and shoulders should be raised and the legs (not the back) used to push the body up. This should be carried out in one smooth motion;

- the load should be held close to the body, the hips and shoulders should be facing the same direction, and the feet should be pointed in the direction of the move.

*If lifting from inaccessible places, a person should brace the knees against something firm, bend from the hips and push the buttocks out behind, maintaining a straight line for the head and back, and lifting with the leg, buttock and stomach muscles. *When carrying a load, it is necessary to hold it close, keeping the elbows turned in, avoiding changing grips without first supporting the load, ensuring the route can be clearly seen, using the feet to change direction (do not twist the body), and turning the feet, shoulders and hips to face the unloading spot. When unloading, the object should be held close, and lowered by bending the knees with the back straight. Fingers and toes should be kept away from the bottom of the load, and the object should be placed onto the edge of the surface and slid into place securely, ensuring that it will not fall, tip over, etc. *A team-lift is safer when:

- lifters are around the same height and build;

- one person calls directions;

- the object is lifted to the hips at the same time and raised to a comfortable level, which is maintained while carrying the load

- movements are smooth and in unison; and

- both persons unload at the same time.

*If lifting from a high place:

- a platform should be used instead of a ladder;

- the load should be lightened into smaller units, where practicable;

- the person should confirm the weight and the stability of the load before lifting; and

- the load should be kept close to the body, grasped firmly and slid down the torso.

*For one-arm lifts the load should be split where possible; the person should lift with legs, balance with the other arm, keep the shoulders level and change hands frequently. *The use of mechanical aids, such as hand trucks, trolleys and wheelbarrows can help to reduce the risk of accidents if used correctly, eg. pushing, rather than pulling the object for more power; staying close to the load and keeping elbows in; maintaining a firm grip; keeping close to the load with the back straight, knees bent and leaning in the direction of movement. The leg muscles and body weight should do the work, rather than the person pushing with their feet, and the load should be kept under control at all times, particularly when moving on slopes. CHECKLIST – MANUAL HANDLING| 1 | Are manual handling operations carried out at your premises? | YES | NO | | 2 | If so, is there a risk of injury from such MHO? | YES | NO | | 3 | Is it reasonably practicable to avoid moving the loads? | YES | NO | | 4 | Is it reasonably practicable to automate or mechanise the operaions? | YES | NO | | 5 | If some risk of manual handling injury remains, have you carried out a manual handling assessment? | YES | NO | | 6 | Have you determined what measures are needed to reduce the risk of injury to the lowest level reasonably practicable? | YES | NO | | 7 | Have all such measures been implemented? | YES | NO | | 8 | Have you carried out suitable and sufficient instruction and training of appropriate employees, including supervisors? | YES | NO | | 9 | Do you have a system to review MHO assessment as necessary? | YES | NO |

REFERENCES/FURTHER DETAILS1.Booklet L23 – Guidance on Regulations – Manual Handling Operations Regulations 1992 (HSE) ISBN 0 7176 2414 3 2.Leaflet IND(G) 143 – Getting to grips with manual handling – a short guide for employers (HSE) ISBN 0 7176 1754 8 3.HSG 115 – Manual handling – solutions you can handle (HSE) ISBN 0 7176 0693 7. 4.Book HSG196 – Moving food and drink. Manual handling solutions for the food and drinks industries (HSE). ISBN 0 7176 1731 9. 5.Leaflet IACL106 – Handling the News-Advice for newsagents and employees on safe handling of bundles. |