Think Health as much as Safety

This week I thought we should look at the Health side of Health & Safety.

Generally the accident rate at work is falling and industry should be applauded for that. But all too often we find that workers forget about or ignore the health aspects of work only to find that they spend their later years in poor health. All of which could have been avoided had they taken simple precautions when they were at work.

So the main article this week is asking you to “Think Health as much as Safety”

This week’s 2 recent HSE cases also look at accidents that could and should have been avoided.

- Mr Deimantas Beinoras, had his arm was pulled around the drill and broke two bones in right forearm. His injuries resulted in skin graft being required on the arm.

- Employees at LJH Group Limited were identified as being at increased risk from working with vibrating tools following a fitness for work assessment.

We hope you learn from the mistakes of others that are highlighted in our weekly newsletters and, as a result, do not have similar accidents at your workplace.

As ever, if you have a subject that you would like us to cover one week, please contact us by phone 01458 253682, email or via our Facebook page or by Twitter.

Think Health as much as Safety

As we stated earlier, generally the accident rate at work is falling and industry should be applauded for that. But all too often we find that workers forget about or ignore the health aspects of work only to find that they spend their later years in poor health. Let’s take a look at some of the main health problems and what we can do to avoid them.

What Health Threats Should You Look Out For?

Dust

Many of the health threats are fairly obvious such as dust. But some dusts are more dangerous than others:

Silica Dust Clouds

The extremely common natural substance Silica is found in stone of all sorts on work sites. It’s released into the air during processes like grinding, sawing, demolition, power cutting, dumping, loading and plenty more.

When Silica is breathed in a lot over time, it causes all kinds of nasty conditions, from silicosis to lung cancer.

Is Face Fit Testing a legal requirement?

Yes, face fit testing is a legal requirement for anyone who wears a tight (or close) fitting mask for work.

The supporting guidance for COSHH (Control of Substances Hazardous to Health), CLaW (Control of Lead at Work), CAR (Control of Asbestos Regulations) and the Ionising Radiation Regulations, stipulate that fit testing should be carried out as part of the initial mask selection process. This ensures that inadequately fitting face pieces are not selected for use.

In an effort to help our clients and anyone else who needs to have a test, The Wilkins Safety Group have trained one of our team, Chris Walton Tech IOSH, PIEMA., to be a qualified face fit tester. As a result, we can now offer this service.

For more info:

Bad Manual Handling

Health and social care more than any other industry, has workers taken out by musculoskeletal problems developed over time.

More than one third of all reportable ‘Over Three Day’ injuries and nearly 10% of ‘Major Injuries’ are associated with manual handling. Many injuries are cumulative, resulting from repeated exposure to manual handling operations. Sprains and strains arise from the incorrect application and/or prolongation of bodily force. Poor posture and excessive repetition of movement can be important factors in onset of injuries.

When bending, lifting, twisting, carrying, and dozens of small movements with heavy or even light loads are carried out repetitively over time, one day it takes its toll!

So what should you do?

1 – Avoiding hazardous Manual Handling

Ask yourself can the movement etc. of loads be eliminated altogether? If the answer is no then ask can the operations be automated or mechanised?

2 – Assessing hazardous Manual Handling

Where a possibility of injury from manual handling is indicated, a more specific assessment should be carried out. This is distinct from the everyday judgements which supervisors and others will have to make dealing with Manual handling. It needs to be broad in approach, identify measures to deal with problems likely to arise and include training provisions. Industry specific data and assessments might prove useful sources of information. The assessment should be recorded and kept readily accessible as long as it remains relevant. It should be noted that assessment is not an end in itself, merely a structured way of analysing risks and pointing the way to practical solutions.

Too Much Noise and Vibration

What is the problem with noise?

Noise is part of everyday life, but too much noise can cause permanent and disabling hearing damage. This can be hearing loss that gets worse over time, damage caused by sudden, extremely loud noises, or tinnitus (permanent ringing in the ears).

With hearing damage, conversation becomes difficult or impossible, your family complains about the television being too loud, you have trouble using the telephone, and you may be unable to sleep. By the time you notice, it is probably too late.

However, there is no need for your hearing to be damaged by your work – your employer has a duty to protect you and should be working on measures to reduce the risk. You can play a part in helping your employer to protect you.

Is there a noise problem where I work?

If any of the following apply, your employer would be expected to be doing something about noise:

- the noise is intrusive – like a busy street, a vacuum cleaner or a crowded restaurant – or worse, for most of the working day;

- you have to raise your voice to have a normal conversation when about 2 m apart, for at least part of the day;

- you use noisy powered tools or machinery for over half an hour a day;

- the type of work is known to have noisy tasks, e.g. construction, demolition or road repair; woodworking; plastics processing; engineering; textile manufacture; general fabrication; forging or stamping; paper or board making; canning or bottling; foundries; waste and recycling;

- there are noises because of impacts (such as hammering, drop forging, pneumatic impact tools etc.), explosive sources such as cartridge-operated tools or detonators, or guns.

Another sign that something should be done about the noise is having muffled hearing at the end of the day, even if it is better by the next morning. If you have any ear or hearing trouble, let your employer know.

Feeling those bad vibrations?

Two million people in the UK are at risk of developing hand-arm syndrome (HAVS) or carpel tunnel syndrome from using power tools like sanders, hammer drills, grinders and dozens more.

At a glance it may seem vibrations from power tools are a minor concern, but too much and you can develop serious and debilitating conditions – like hand-arm Vibration syndrome (HAVS) or carpel tunnel syndrome.

Their more unpleasant nicknames illustrate better how bad these injuries are – ‘vibration white finger’ or ‘dead finger’. Yep, ‘dead finger’ doesn’t sound too minor does it.

HAVS causes pain and distress, reduced ability to work in damp or cold conditions, or to do any fine work with the fingers, and loss of strength in the hands – all pretty much what a good builder needs for their livelihood!

So what’s the threat and how can you avoid it?

6 Signs Your Workers are at Risk of HAVS

- They work in construction – that’s right, everyone in construction is at risk of HAVS, it’s the most common industry for the problem

- Your employees complain about numbness or tingling in their hands and fingers when they’ve been using vibrating tools

- They hold work pieces that vibrate because they are being processed by pedestal grinders or other power machinery

- They operate any hammer action tool for more than 15 minutes a day

- They use rotary or other action tools for over 1 hour a day

- They regularly use hand-held or guided power tools like Sanders, grinders, disc cutters, Hammer drill etc.

So you can see how the HSE can say 2 million people in the UK are at risk of getting HAVS – but before you panic, that’s 2 million at risk! You can take these steps to dramatically reduce that risk. Pay careful attention to any signs of HAVS symptoms;

4 Early Symptoms of HAVS

- Numbness or tingling in fingers

- Reduced sense of touch

- Hands losing strength

- Whiteness in your fingers, and then redness and pain

But you should be taking action a long time before you see symptoms. They can show up after months or years of exposure. A little too late. Instead, take these precautions and make sure all your workers know them well and follow them;

7 Ways to Reduce the Risk of HAVS

- Reduce the time you use a tool in one go – vary, alternate and break up jobs

- Use low-vibration tools wherever it’s possible

- Maintain and check tools – when they’re not taken care of properly wear, tear and faults can cause extra vibrations

- Don’t force a tool too much

- Don’t grip a tool harder than is necessary to do a job

- Try to keep the tool handles not too cold – so store them inside when possible

- Always keep yourself warm and dry – this helps the blood circulation in your hands and arms

Work related stress

Well-designed, organised and managed work is good for us but when insufficient attention to job design, work organisation and management has taken place, it can result in Work related stress.

Work related stress develops because a person is unable to cope with the demands being placed on them. Stress, including work related stress, can be a significant cause of illness and is known to be linked with high levels of sickness absence, staff turnover and other issues such as more errors.

Stress can hit anyone at any level of the business and recent research shows that work related stress is widespread and is not confined to particular sectors, jobs or industries. That is why a population-wide approach is necessary to tackle it.

Definition of stress

HSE’s formal definition of work related stress is:

“The adverse reaction people have to excessive pressures or other types of demand placed on them at work.”

Stress is not an illness – it is a state. However, if stress becomes too excessive and prolonged, mental and physical illness may develop.

There is a difference between pressure and stress. Pressure can be positive and a motivating factor, and is often essential in a job. It can help us achieve our goals and perform better. Stress occurs when this pressure becomes excessive. Stress is a natural reaction to too much pressure.

If you need further information please call us on 01458 253682 or send us an email.

Face Fit Testing Service

This is the latest service offered by The Wilkins Safety Group

Why do I need Face Fit Testing?

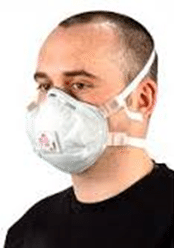

Ill-fitting Respiratory protective equipment (RPE) can lead to respiratory problems if harmful substances are released into the air supply. And so if your work requires tight fitting face protection then by law, a face fit test is required to ensure the equipment fits the face of the user, protecting them from exposure to harmful substances.

Is Face Fit Testing a legal requirement?

Yes, face fit testing is a legal requirement for anyone who wears a tight (or close) fitting mask for work.

The supporting guidance for COSHH (Control of Substances Hazardous to Health), CLaW (Control of Lead at Work), CAR (Control of Asbestos Regulations) and the Ionising Radiation Regulations, stipulate that fit testing should be carried out as part of the initial mask selection process. This ensures that inadequately fitting face pieces are not selected for use.

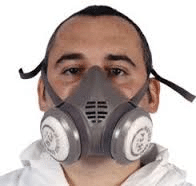

Which masks need to be tested?

Face fit testing is required for all of the following types of masks:

Does a face fit test take a long time?

Face Fit Testing is simple and straightforward, requiring little time to complete. It is undertaken by a fully qualified competent trainer, who will ensure the equipment is perfect for the wearer. It can be completed in-house, lasting as little as 15 to 20 minutes.

What does the test involve?

There are two types of test.

The qualitative test can only be carried out on half masks. The test takes around 20 minutes and involves wearing a hood over the head and shoulders. The tester sprays a bitter tasting solution into the hood whilst the delegate carries out a series of exercises, i.e. turning head from side to side. If the wearer can taste the solution, then the mask does not fit correctly.

The quantitative test can be carried out on any type of mask. There are several different methods for this test. The most common method involves attaching the mask to a machine (a Portacount), which can detect whether airborne particles are passing into the mask through the seal. Again the test takes around 20 minutes and at the end of the test the machine gives a ‘pass’ or ‘fail’.

When should I book a test?

Face fit tests should be booked to coincide with the initial choosing of the equipment. If you already have tight-fitting face masks that remain untested but in use, you should consider it a priority to book a test, so that you are compliant with the law, and protecting your employees.

Is the test only carried out once?

It is recommended that you re-test the RPE regularly, and especially if the wearer has:

just to ensure that the mask still fits and is protecting the employee.

Who can carry out a face fit test?

A competent person should carry out a face fit test. Competency can be proven by accreditation to the BSIF Fit2Fit Fit Testers Accreditation Scheme, however this is not compulsory. Manufacturers of fit test equipment may also provide competency training and evaluation and proof of these may be sufficient to prove competency.

Where can I find out more information?

Government legislation can be found here.

Can I book through The Wilkins Safety Group?

The Wilkins Safety Group can provide face fit testing across the UK from £150 + VAT. (Prices dependant on number of Face Fit Tests required and test location).

To enquire or book: Tel – 01458 253682 or email.