Polythene firm sentenced over employee’s life changing injuries

A Widnes film polythene manufacturer has been fined a total of £40,000 for serious safety breaches after an employee was badly injured when he became trapped in a machine.

British Polythene Ltd was prosecuted today by the Health and Safety Executive (HSE) following an incident at BPI Widnes Films, Warrington Road on 21 January 2014.

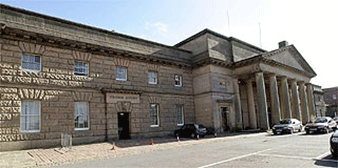

Chester Crown Court heard the worker’s upper body was trapped for over a minute before being freed by colleagues, during which time he received injuries to his kidney, spleen and lungs. He was taken to hospital, where he spent three days in intensive care, and has lost function of one kidney.

The employee was working during a night shift, operating ‘multi-winders’ that convert ‘logs’ of stretch film polythene into smaller hand sized reels. The ‘logs’ are held in position for unwinding by two pneumatic arms, known as pivot or lift arms.

During a short delay before the arms were activated, the worker walked down the machine checking there was no damage to the film. He noticed a piece of debris which could cause damage to the roll, but as he attempted to remove it he was trapped by the pivot arm.

The company had previously identified a risk relating to pivot arms on similar winding machinery and had implemented the correct control measures. HSE told the court that had the same approach been applied to this machine, and had the company taken appropriate precautions and measures to ensure safety when using the equipment, the employee’s life-changing injuries could have been prevented.

British Polythene Ltd of One, London Wall, London pleaded guilty to breaches of Regulation 11 of the Provision and Use of Work Equipment Regulations 1998 and Regulation 3 (1) of the Management of Health and Safety at Work Regulations 1999.

The company was fined £20,000 for each breach and ordered to pay prosecution costs of £10,033.

Speaking after the hearing, HSE Inspector Adam McMahon said:

“If a suitable and sufficient risk assessment had been completed the necessary control measures could have been implemented to prevent the accident from occurring.”